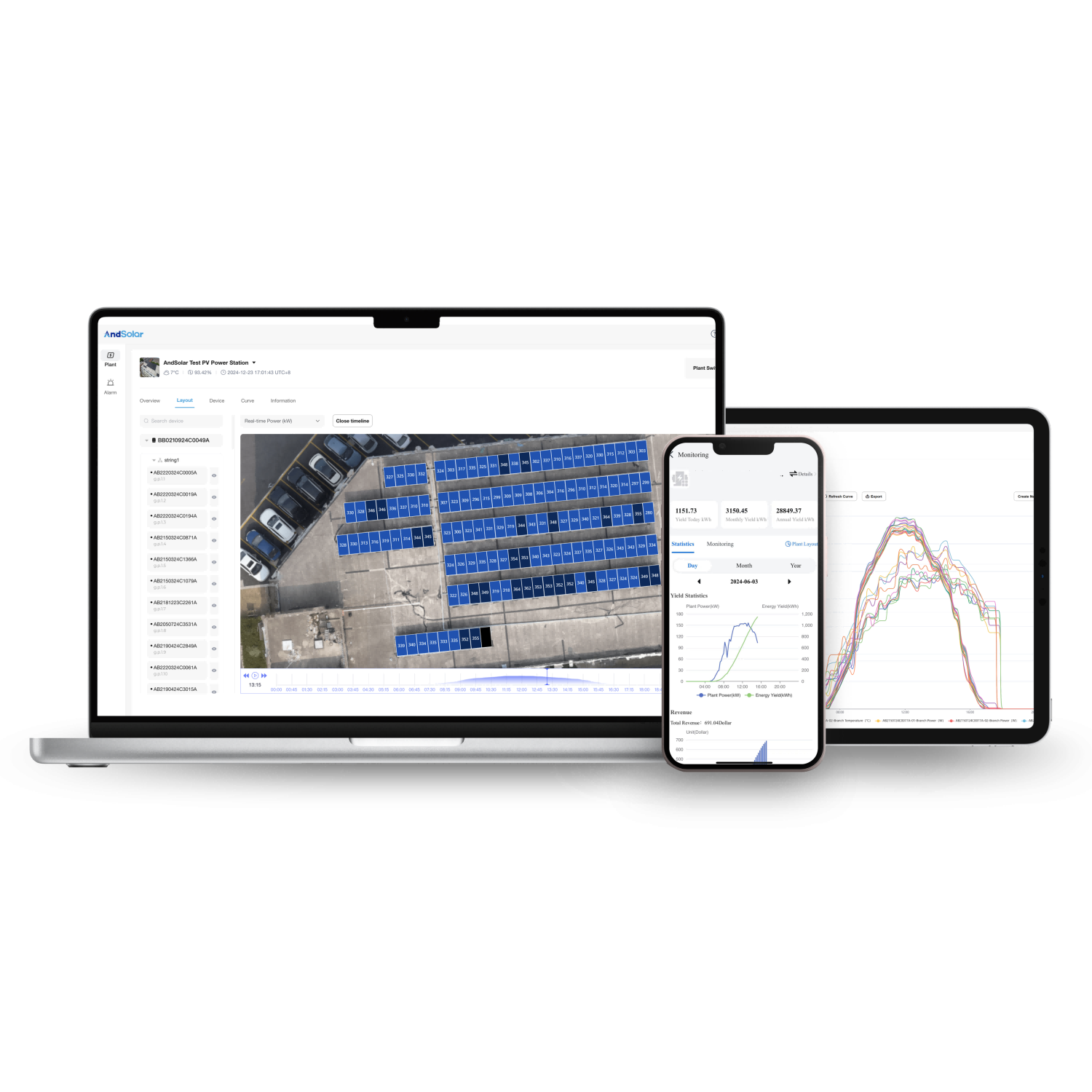

rsd with data monitoring

The rsd with data monitoring represents a revolutionary approach to real-time system diagnostics and performance analysis, combining sophisticated monitoring capabilities with advanced data processing technologies. This comprehensive solution delivers unprecedented visibility into system operations, enabling organizations to maintain optimal performance while preventing costly downtime. The rsd with data monitoring system integrates seamlessly with existing infrastructure, providing continuous surveillance of critical metrics and parameters that determine operational efficiency. At its core, this technology employs advanced algorithms to collect, analyze, and interpret vast amounts of operational data in real-time. The system utilizes cutting-edge sensors and data acquisition modules that capture information from multiple sources simultaneously, ensuring comprehensive coverage of all monitored parameters. The rsd with data monitoring solution features intelligent alerting mechanisms that notify administrators immediately when anomalies or threshold violations occur, enabling rapid response to potential issues. The technological architecture incorporates cloud-based analytics platforms that leverage machine learning algorithms to identify patterns and predict potential failures before they impact operations. This predictive capability distinguishes the rsd with data monitoring from traditional monitoring solutions, offering proactive rather than reactive maintenance strategies. The system supports multiple communication protocols and interfaces, ensuring compatibility with diverse hardware configurations and legacy systems. Applications span across numerous industries, including manufacturing, energy, telecommunications, and healthcare sectors. In manufacturing environments, the rsd with data monitoring optimizes production line efficiency by tracking equipment performance and identifying bottlenecks. Energy sector implementations focus on grid stability and resource optimization, while telecommunications applications ensure network reliability and service quality. The healthcare industry benefits from enhanced patient monitoring capabilities and medical equipment oversight, ensuring compliance with stringent safety standards and regulatory requirements.