Understanding Modern Solar Panel Efficiency Technologies

As solar energy systems become more mainstream for residential and commercial applications, the conversation has moved beyond panels themselves to the technologies that enhance their performance. Two standout innovations—microinverters and optimizers—are revolutionizing how energy is converted, monitored, and managed at the panel level. While both microinverters and optimizers serve the goal of maximizing efficiency, they function in distinctly different ways. Understanding these differences is crucial for system designers, installers, and end-users who want to make informed decisions about their solar setups. This blog explores the critical aspects of both technologies, from performance and efficiency to safety, installation, and long-term value.

Performance and Power Conversion Capabilities

How Microinverters Enhance Module-Level Efficiency

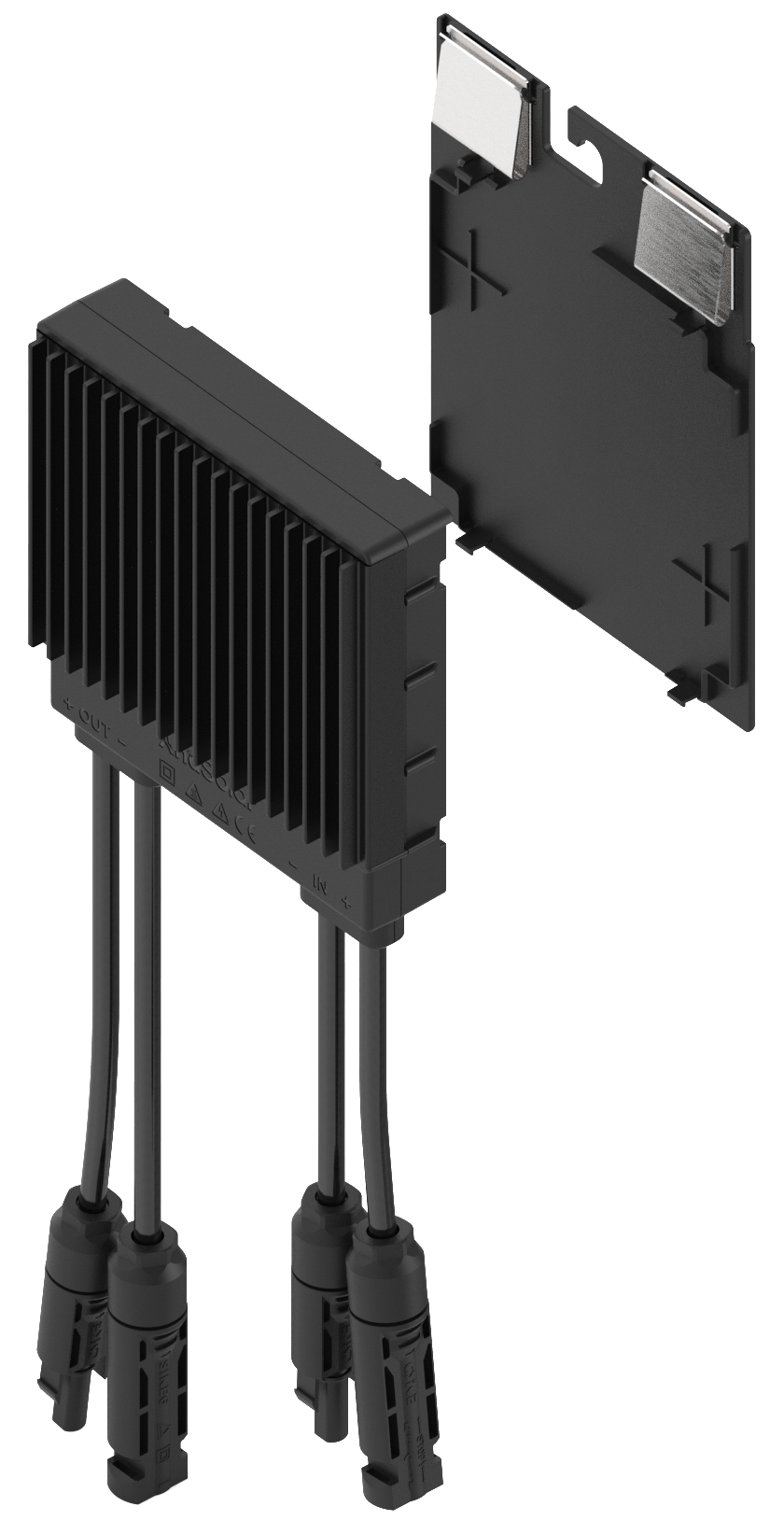

Microinverters are devices installed directly on the back of each solar panel, allowing every module to operate independently and convert DC electricity to AC right at the source. This decentralized approach means that each panel performs at its optimal level regardless of the performance of surrounding panels. In practical terms, microinverters are especially useful in situations where shading, dirt, or roof obstructions impact just part of the array. Instead of dragging down the output of the whole system, affected panels only impact their own performance. This characteristic greatly enhances energy yield over time and provides users with a more reliable and predictable energy supply.

The Role of Optimizers in Maximizing System Output

Optimizers, unlike microinverters, work by conditioning the DC power produced by each solar panel before sending it to a centralized inverter. This allows the system to isolate each panel’s performance while still converting power centrally. Optimizers offer many of the same benefits as microinverters in terms of improving output from shaded or mismatched panels, but with a slightly different technical configuration. Because the conversion to AC happens at a single point, the system remains somewhat centralized. Nevertheless, optimizers make a traditional inverter system much more adaptable and efficient without completely overhauling the existing architecture.

Monitoring and Troubleshooting Features

Real-Time Panel-Level Data with Microinverters

One of the most appreciated features of microinverters is their ability to deliver detailed, real-time data for every panel in the system. With microinverters, users can monitor the output of each module through intuitive apps or web dashboards. This capability is not only valuable for energy tracking but also instrumental for troubleshooting. If a panel underperforms or fails, it can be quickly identified without the need for physical inspection or system-wide diagnostics. This visibility improves maintenance efficiency and allows for timely repairs, which helps keep the entire system running at maximum capacity.

Diagnostic Benefits Provided by Optimizers

Optimizers also allow for module-level monitoring, offering a similar ability to track performance across the array. Users and installers can access real-time insights into how each panel is functioning and identify issues such as shading, degradation, or electrical problems. While optimizers depend on a central inverter for AC conversion, they still report data individually, ensuring that maintenance can be precise and efficient. This level of oversight is especially valuable for larger installations or commercial settings where any downtime can translate into significant financial loss. The ability to detect and address problems early adds substantial value to systems using optimizers.

Safety and Compliance Considerations

How Microinverters Support Enhanced Electrical Safety

Microinverters are often lauded for their inherent safety features, particularly because they eliminate high-voltage DC lines across the roof. Since the DC-to-AC conversion happens at the panel itself, the risk of arc faults or electrical fires is significantly reduced. This design meets or exceeds many national and international safety standards, including rapid shutdown requirements. In residential and commercial environments where fire codes and insurance regulations are stringent, microinverters offer peace of mind while also simplifying compliance. Their safe, decentralized operation model makes them an attractive option for safety-conscious installers and customers.

Safety Innovations in Optimizer Systems

While optimizers do not convert DC to AC at the module, they do provide features like voltage regulation and arc fault detection that enhance overall system safety. Many optimizers are equipped with rapid shutdown capabilities to comply with modern electrical codes. In the event of a fire or emergency, the system can quickly reduce voltage to safe levels, protecting both the structure and personnel. Although the centralized inverter in an optimizer system still requires attention to wiring and placement, the safety protocols embedded in the optimizers themselves add a crucial layer of protection, especially in large-scale or complex installations.

Installation Flexibility and Design Advantages

Versatile Applications Enabled by Microinverters

Microinverters offer unmatched flexibility when designing a solar installation. Because each panel operates independently, they are ideal for complex rooftops with varying angles, orientations, or obstructions like chimneys and skylights. Installers can place panels wherever space is available without worrying about impacting the rest of the array. This makes microinverters particularly beneficial for retrofitting older buildings or optimizing irregular roof spaces. Furthermore, system scalability is seamless—users can add panels later without modifying the entire setup, making microinverters a future-proof choice for growing energy needs.

Design Compatibility and Adaptability of Optimizers

Optimizers strike a balance between centralized and distributed systems. They offer enough flexibility to accommodate irregular layouts while maintaining some of the design simplicity of traditional inverter setups. Optimizers allow panels facing different directions or at various tilt angles to perform independently, which is a significant upgrade from conventional string configurations. Additionally, since optimizers still rely on a centralized inverter, the system can benefit from economies of scale, reducing costs in larger installations. This hybrid approach makes optimizers well-suited for projects that require both flexibility and cost-effectiveness.

Cost Structure and Financial Implications

Initial Investment and Long-Term Value of Microinverters

Microinverters tend to have a higher upfront cost due to the need for one device per panel. However, this investment often pays off through improved energy yields, reduced maintenance costs, and enhanced system longevity. Over the lifetime of the system, microinverters can offer a more attractive return on investment, especially in areas where shading or variable sunlight is a concern. Additionally, the ability to monitor and maintain the system more efficiently reduces operational costs and system downtime. For many users, these long-term benefits outweigh the initial price difference when compared to optimizer-based solutions.

Cost-Effectiveness of Optimizers in Larger Systems

Optimizers offer a more cost-effective alternative to microinverters in many cases, particularly for larger installations. Because the power conversion still occurs at a centralized inverter, fewer components are needed, reducing material and labor costs. Optimizers also make it possible to enhance an existing traditional inverter system without replacing the entire setup. This modular upgrade path appeals to budget-conscious users who want improved efficiency without a full system overhaul. While they may not offer the same level of isolation and fault tolerance as microinverters, optimizers provide an excellent balance of performance and affordability.

Maintenance and Operational Simplicity

Reduced Downtime with Microinverter-Based Systems

Microinverter systems are known for their resilience and ease of maintenance. Since each panel functions independently, the failure of a single unit does not impact the rest of the array. Moreover, panel-level monitoring allows problems to be detected and addressed quickly, minimizing disruption. In the event that a microinverter fails, it can usually be replaced without affecting the overall system. This decentralized architecture improves uptime and ensures that energy production continues without major interruptions, which is particularly important for mission-critical installations or remote locations.

Efficient Troubleshooting in Optimizer Systems

Although optimizers rely on a central inverter, they still offer many advantages when it comes to maintenance. The ability to monitor each panel individually helps in diagnosing issues early and accurately. Most optimizer systems provide alerts and detailed data, allowing installers to address concerns before they escalate. Replacement of faulty components is straightforward, and the modular design means repairs can be localized. While a centralized inverter may require occasional maintenance, the overall ease of managing an optimizer-based system is significantly better than that of traditional string inverter setups.

Environmental Impact and System Longevity

Sustainability Benefits of Microinverter Systems

The longer operational life and high energy conversion efficiency of microinverters contribute to a lower environmental footprint over the life of the system. Reduced energy loss translates to better carbon offset, making microinverters a more sustainable option for eco-conscious users. Additionally, fewer service calls and component failures reduce waste and the need for replacements. The system’s ability to maintain high performance in variable conditions also ensures that users get the maximum environmental benefit from their solar investment. For those prioritizing long-term sustainability, microinverters offer compelling advantages.

Durable Design and Resource Efficiency of Optimizers

Optimizers are engineered for durability and designed to work with long-life central inverters. By improving the output of each panel and enhancing fault detection, optimizers help preserve the system’s overall performance for years. They also allow system owners to replace only the faulty component without dismantling the entire system. This modularity reduces waste and contributes to better resource management. When combined with their affordability and flexibility, the sustainable design of optimizers makes them an appealing choice for environmentally responsible installations.

FAQ

What is the main difference between microinverters and optimizers?

Microinverters convert DC to AC at each panel, allowing independent operation, while optimizers condition DC power at the panel but use a central inverter for AC conversion.

Are microinverters more efficient than optimizers?

Microinverters typically provide better performance in shaded or complex roof conditions, while optimizers offer similar benefits at a lower cost in uniform installations.

Which system is safer: microinverters or optimizers?

Both offer enhanced safety features, but microinverters reduce rooftop voltage more effectively by converting power at the source, minimizing fire and electrical hazards.

Can I upgrade an existing system with microinverters or optimizers?

Yes, optimizers are easier to retrofit into existing systems with string inverters, while microinverters are more suited for new installations or complete system overhauls.

Table of Contents

- Understanding Modern Solar Panel Efficiency Technologies

- Performance and Power Conversion Capabilities

- Monitoring and Troubleshooting Features

- Safety and Compliance Considerations

- Installation Flexibility and Design Advantages

- Cost Structure and Financial Implications

- Maintenance and Operational Simplicity

- Environmental Impact and System Longevity

- FAQ