Enhanced Energy Production with MLPE

Mitigating Shading and Mismatch Losses

Efficient energy production in photovoltaic systems is often sabotaged by shading and mismatch losses, but Module-Level Power Electronics (MLPE) effectively tackle these challenges. Shading can drastically reduce the performance of solar panels in traditional systems, where panels are interconnected; a shadow on one panel triggers a ripple effect, lowering the entire system's efficiency. By allowing each panel to operate independently, MLPE minimizes the impact of shading, ensuring consistent energy output. Research indicates that traditional systems can lose up to 30% of energy due to shading alone. In contrast, MLPE isolates affected panels, allowing others to maintain full capacity. Additionally, mismatch losses, caused by variations in panel performance due to manufacturing discrepancies or environmental factors, are mitigated by MLPE. This technology fine-tunes each panel's output, enhancing overall system efficiency.

Maximizing Output Through Module-Level Optimization

The concept of module-level optimization central to MLPE significantly boosts energy output, ensuring each panel performs optimally. In practice, MLPE technologies such as microinverters and power optimizers provide real-time adjustments to the performance of individual modules, significantly enhancing system efficiency. Real-world examples highlight the effectiveness of MLPE in increasing energy production. For instance, studies have shown that systems implementing MLPE can experience up to a 20% increase in energy output compared to traditional setups. These real-time adjustments reduce inefficiencies tied to environmental or technical variations, positioning MLPE as a superior choice over traditional systems. By focusing on module-specific performance, MLPE ensures no panel is underutilized, offering substantial performance advantages over static systems, and maximizing the return on investment.

Improved Safety and System Reliability

Rapid Shutdown Capabilities for Fire Safety

Rapid shutdown capabilities play a crucial role in maintaining fire safety in solar installations, particularly in commercial photovoltaic systems. The National Electric Code (NEC) introduced stringent requirements in 2014, which aimed to enhance fire safety by ensuring rapid shutdown mechanisms could deactivate system voltage within a specified boundary. According to various studies, these mechanisms significantly reduce risks during emergencies by enabling quick deactivation, thereby preventing electrical fires. Compliance with these standards is not only a safety measure but also a regulatory necessity to mitigate hazards during fire incidents (source: Solar Builder Magazine).

Voltage Control at the Module Level

Voltage control at the module level is instrumental in enhancing system safety and reliability in solar installations. By allowing precise control over voltage at each panel, these systems can minimize risks such as electrical faults, which are critical in maintaining the safety of photovoltaic systems. For instance, the use of MLPE technologies like microinverters and optimizers ensures that the voltage at each module can be adjusted independently, reducing the risk of faults and increasing system reliability. Furthermore, MLPE compliance with international safety standards further assures system safety, making it a key element in modern solar system design (source: Solar Builder Magazine).

Advanced Monitoring and Diagnostics

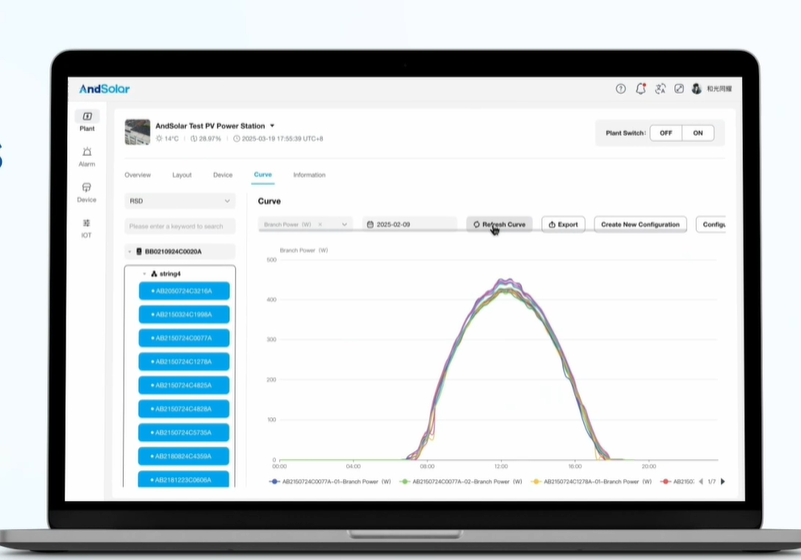

Real-Time Performance Tracking

Real-time performance tracking plays a vital role in maximizing the efficiency and output of commercial photovoltaic systems. By continuously monitoring the performance of each solar panel, operators can identify trends and detect potential inefficiencies or issues as they arise, enhancing overall system reliability. Experts from the industry highlight that constant monitoring not only facilitates proactive maintenance but also significantly improves productivity as it allows operators to address issues promptly before they escalate. For instance, systems with real-time performance tracking typically exhibit marked improvements in overall energy management, leading to enhanced operational efficiency and reduced costs.

Identifying Module-Level Faults Efficiently

Module-Level Power Electronics (MLPE) facilitate quick identification of faults at the module level, ensuring minimal downtime and preventing extensive damage. By diagnosing issues at the source, MLPE enables early fault detection and allows operators to address problems before they adversely affect the entire photovoltaic system. This capacity is especially beneficial in preventing operational inefficiencies and maintaining system stability. Case studies comparing MLPE systems with traditional setups reveal that MLPE systems significantly reduce response times to faults, thus maintaining higher performance and reliability. This quick diagnosis not only safeguards against extensive damage but also optimizes system maintenance by focusing efforts precisely where they are needed.

Overcoming O&M Challenges in Commercial PV

Reducing Downtime with Targeted Troubleshooting

Quicker diagnostics and corrective actions are paramount in minimizing downtime for commercial photovoltaic systems, and MLPE stands at the forefront of these efforts. By enabling precise diagnostics at the module level, MLPE facilitates immediate identification and resolution of system issues, reducing the overall system downtime. Studies have shown a substantial decrease in average downtime — approximately 15% to 25% — when systems integrate MLPE compared to traditional setups, underscoring the efficiency and reliability of targeted troubleshooting. Additionally, this approach not only restores functionality promptly but also enhances the operational efficiency of photovoltaic systems as a whole, allowing them to deliver consistent power output.

Streamlining Maintenance Costs in Distributed Systems

MLPE plays a crucial role in reducing maintenance costs, especially within distributed photovoltaic systems. Traditional O&M strategies often involve routine checks and physical inspections, which can be costly and time-consuming. However, MLPE revolutionizes this by facilitating remote monitoring and troubleshooting, significantly lowering the need for physical interventions. When comparing with traditional approaches, the integration of MLPE can lead to long-term cost savings, attributed to fewer site visits and automated diagnostics, potentially saving O&M providers 15-25% annually on maintenance expenses. Thus, MLPE not only enhances operational efficiency but transforms maintenance into a more economically viable process by easing logistical challenges across widespread installations.

FAQ Section

What is Module-Level Power Electronics (MLPE)?

MLPE refers to technologies such as microinverters and power optimizers that enhance solar panel efficiency by allowing individual panel performance control.

How does MLPE mitigate shading and mismatch losses?

MLPE allows each panel to function independently, minimizing the impact of shading and mismatch losses by isolating affected panels.

What are the benefits of real-time performance tracking?

Real-time performance tracking helps in identifying trends, detecting inefficiencies, and facilitating proactive maintenance, improving overall productivity.

How does MLPE contribute to fire safety?

MLPE enhances fire safety by ensuring rapid shutdown capabilities, which promptly deactivate the system voltage during emergencies.

Why is MLPE considered cost-effective for system maintenance?

MLPE reduces maintenance costs by enabling remote monitoring, reducing the need for physical interventions, and leading to long-term cost savings.